Deppe – Solid-Wood & Coated Profiles

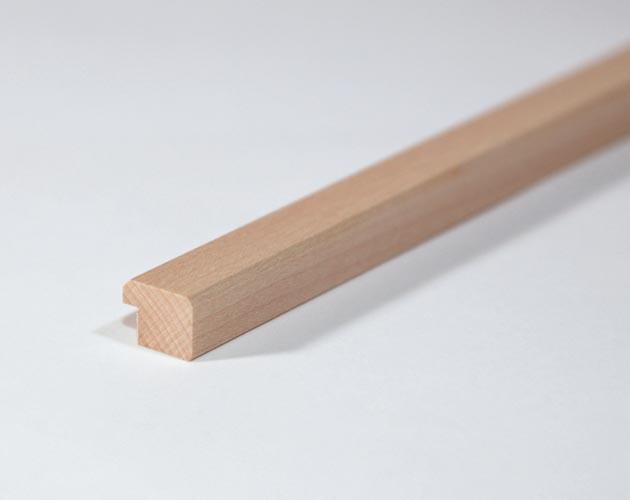

We started our business in 1973 with the production of solid-wood profiles.

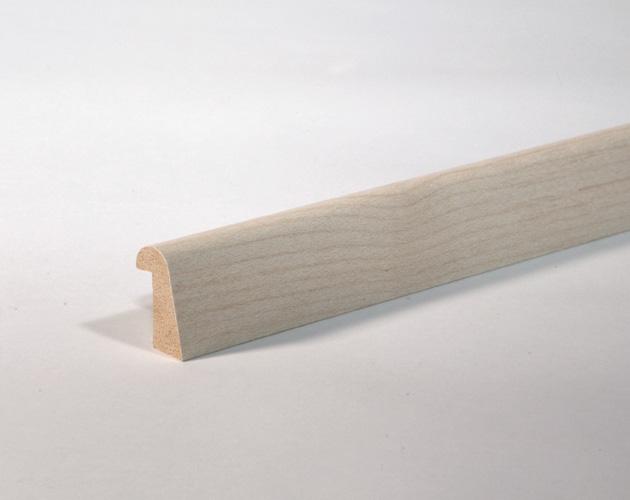

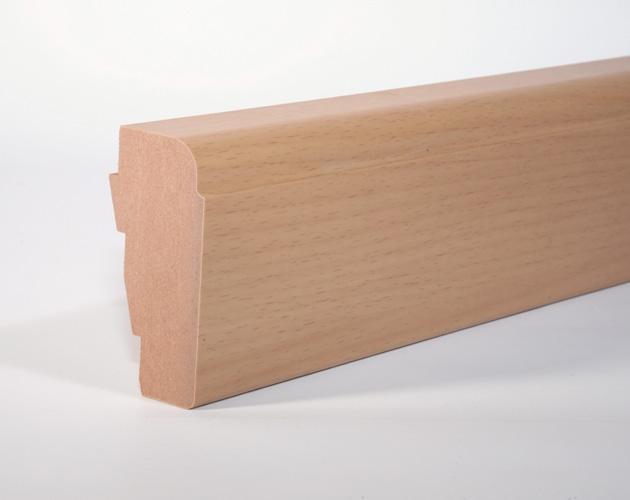

45 years of know-how make sure that specially selected and fist-class wood from Europe or North America is used. Based on up-to-date furniture designs, we mainly employ slightly steamed beech and European oak.

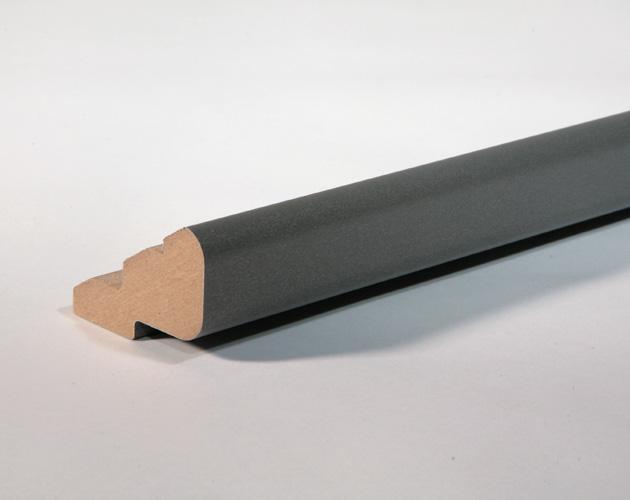

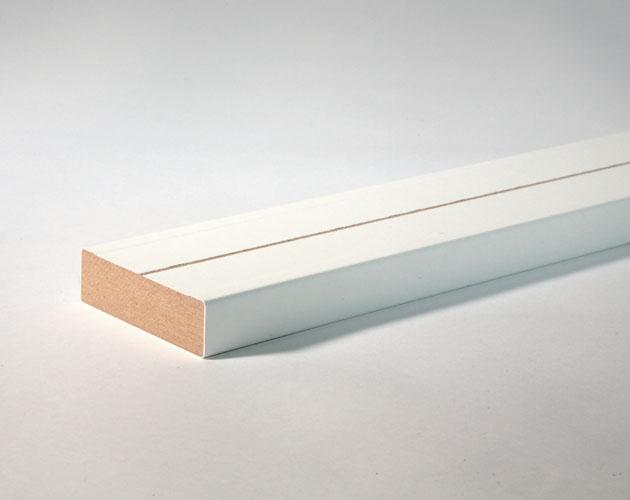

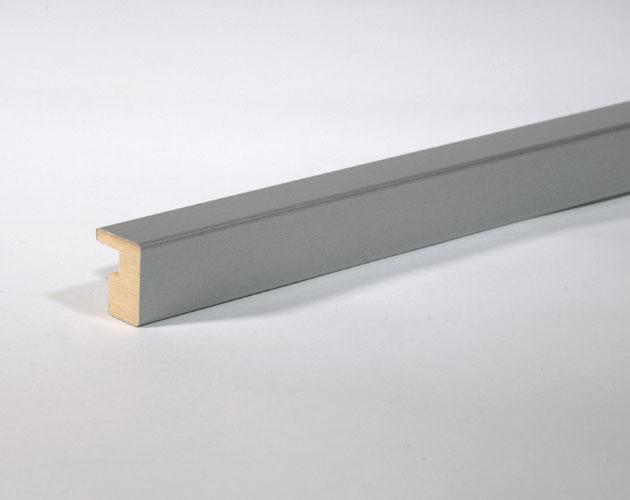

Today, our core business is profile coating – a product division which was introduced in 1991. A wide variety in the selection of core materials and decors allows extremely versatile applications.

Production

Our processing depth includes

- Cutting

- Profiling

- Coating

- Finishing

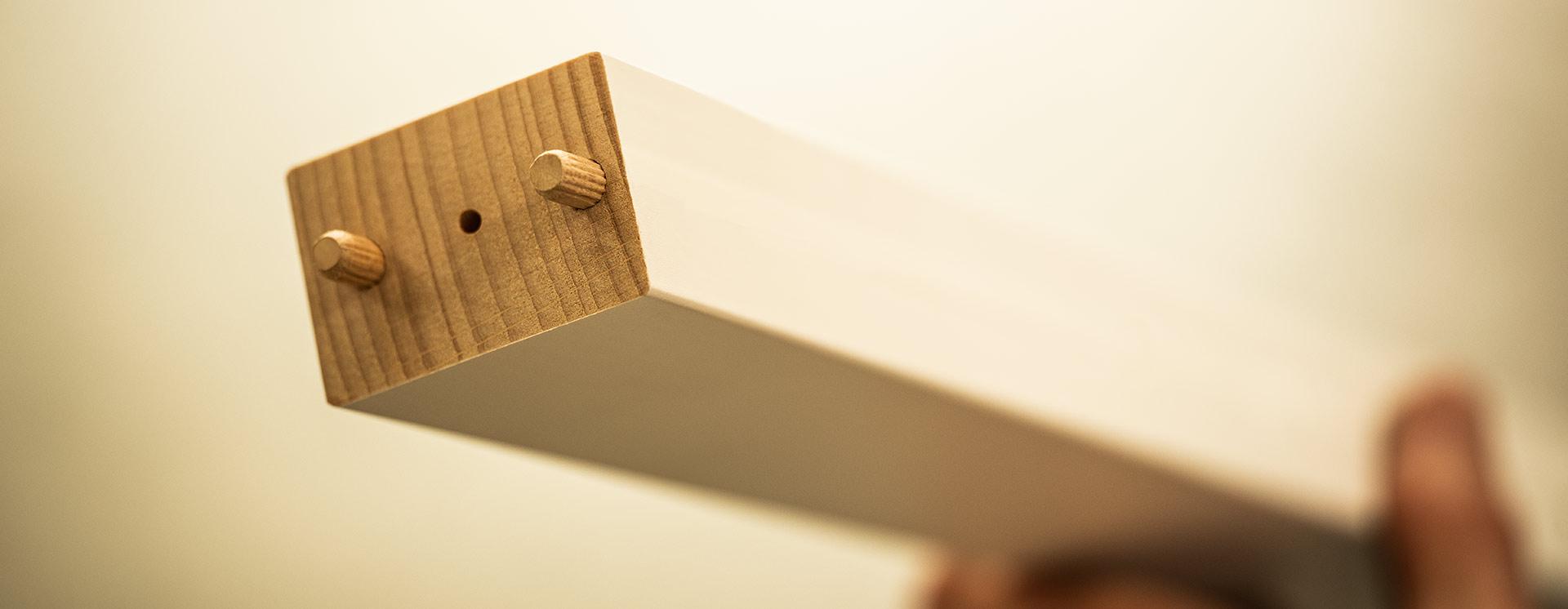

Covering the whole spectrum of processing enables us to offer solid-wood and foil-coated profiles that are ready for immediate use.

After cutting, we start manufacturing the requested profile forms.

Our stock of machinery includes two CNC moulders.

The necessary moulding cutter knives are manufactured in our in-site tool grinding department. This allows a quick and flexible fabrication.

Our coated profiles are manufactured on two machines.

Adhesive application is done by slot dies, ensuring thus an efficient and even application. Unless this is not desired, we use only PUR glues for our profiles.

The pre-cut of employed foils to their necessary width is done in-site. The fact that we have a wide range of foils and veneers on stock a fast and flexible reaction to customer demands.

The surface of our solid-wood and veneer-coated profiles is refined through the use of grinding machines.

Grinding thus serves as a pre-treatment by equalizing the profile surface and improving paint-bonding.

Conditioning of the raw profiles is carried out by the use of DD or NC varnishes.

We always adhere to our customers’ colour specifications. These may be solid wood or wood composite samples as well as e.g. RAL colours.

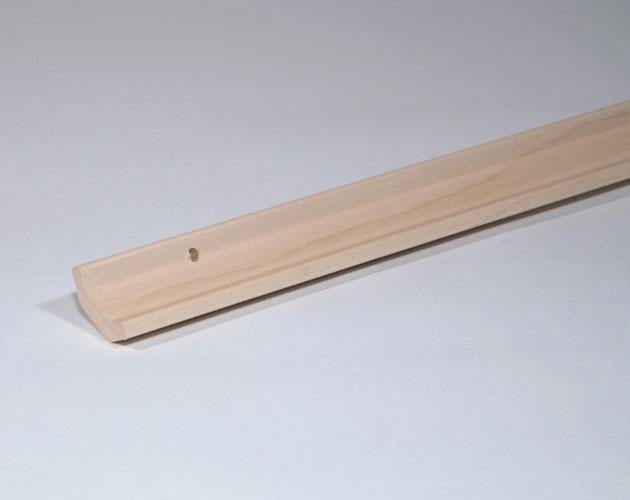

Subsequent processing of the solid-wood and coated profiles is always carried out according to our customers’ requirements.

This includes e.g. cutting to length, framing, milling, drilling, plugging, and coating of front edges as well as customized packaging.

Wood Species and Material Components

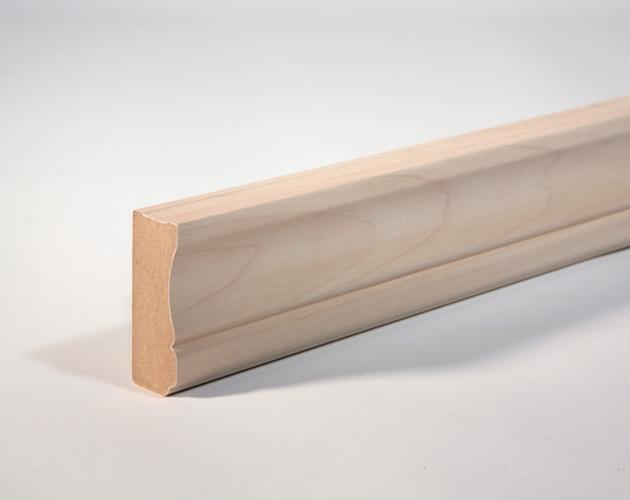

We use hardwood timber in different specially selected qualities for the production of our solid-wood profiles, depending on the required field of application.

We have got a continuous stock of high-class trendy wood species like beech, beech heartwood, and European oak.

Generally, we can supply profiled mouldings in every sustainably grown wood species.

For coated profiles, our customers may choose between different possible combinations:

- Core materials (MDF, chipboard / FPY, solid wood, aluminium)

- Surfaces and decors (veneers and foils)

- Glues (PUR glue)

This guarantees that the wood we employ comes from forests which are managed on the basis of precisely defined principles.

Examples of Use

Due to a great variety of our solid wood and coated profiles, they can be used in many different fields of the furniture industry.

Contact Persons

Ralf Deppe

Managing director

Sales

Tel: +49 (0) 5246/9600-15

Klaus Eichfeld

Order management national

Tel: +49 (0) 5246/9600-10

Dietmar Kaller

Production planning

Tel: +49 (0) 5246/9600-12

Dirk Kemper

Order management national

Tel: +49 (0) 5246/9600-19

Andrea Rempe

Order management international/Deppe24

Tel: +49 (0) 5246/9600-23